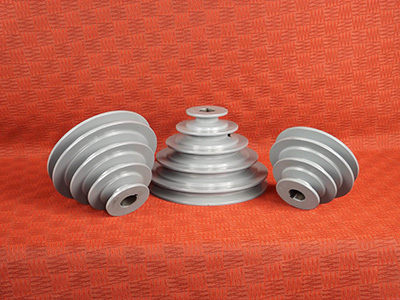

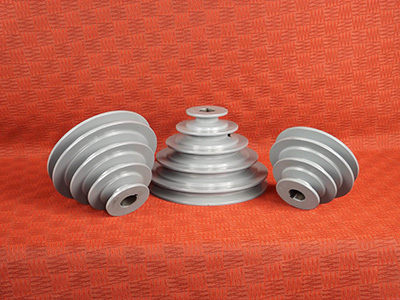

Step Pulley with Bearings

Step Pulley with Bearings

Introduction

A step pulley with bearings is a type of pulley system that is commonly used in various industries. It consists of a series of pulleys with different diameters, arranged in a step-like configuration. The pulleys are mounted on bearings, which allow them to rotate smoothly. This design provides versatility and flexibility in power transmission applications.

Why do we use stepped pulleys?

Variable Speed Control

One of the main reasons for using a stepped pulley is its ability to provide variable speed control. By changing the position of the drive belt on different pulley steps, the rotational speed of the driven shaft can be adjusted. This is essential in applications where different speeds are required for different tasks.

Power Transmission Efficiency

Stepped pulleys with bearings offer high power transmission efficiency due to the smooth rotation provided by the bearings. This ensures minimal energy loss during the transmission process, resulting in improved overall system performance.

Load Handling Capability

The bearings used in step pulleys enhance their load handling capability. They can withstand heavy loads without compromising the smooth operation of the system. This makes step pulleys with bearings suitable for applications that involve heavy-duty tasks.

Noise Reduction

The bearings in step pulleys reduce the friction and noise produced during operation. This helps in creating a quieter work environment, especially in settings where noise control is important, such as laboratories or precision manufacturing facilities.

Increased Durability

Step pulleys with bearings are designed to be highly durable and long-lasting. The bearings protect the pulleys from excessive wear and tear, extending their lifespan and reducing the need for frequent replacements. This makes them a cost-effective solution for industries that require reliable and durable power transmission components.

What is a stepped cone pulley used for?

Variable Speed Applications

A stepped cone pulley is primarily used in applications that require variable speed control. By adjusting the position of the drive belt on different steps of the pulley, the rotational speed of the driven shaft can be changed accordingly. This is advantageous in tasks that involve varying speeds for different processes.

Machine Tools

Stepped cone pulleys find extensive use in machine tools, such as lathes and milling machines. These pulleys allow operators to adjust the speed of the tool’s spindle, enabling precise machining operations based on the material being worked on and the desired outcome.

Industrial Equipment

Various industrial equipment, such as conveyor systems, mixers, and pumps, utilize stepped cone pulleys for speed control. This enables efficient and reliable operation of the equipment, ensuring optimal performance and productivity in industrial settings.

Automotive Applications

In the automotive industry, stepped cone pulleys are commonly found in vehicles’ transmission systems. They facilitate smooth gear shifting and enable the engine to operate at different speeds, depending on the driving conditions. This improves fuel efficiency and enhances overall driving experience.

Printing Presses

Printing presses require precise control over the speed of the printing cylinders. Stepped cone pulleys play a crucial role in achieving this control, allowing for accurate and high-quality printing results.

Types of Pulleys

There are three main types of pulleys: fixed pulleys, movable pulleys, and compound pulleys. Each type has its own advantages and applications.

Fixed Pulleys

Fixed pulleys are stationary and do not change the direction of the applied force. They are commonly used in lifting systems and can provide mechanical advantage by distributing the load over multiple ropes or cables.

Movable Pulleys

Movable pulleys are attached to the load being moved and change the direction of the applied force. They are often used in combination with fixed pulleys to create a block and tackle system, allowing for easy lifting of heavy objects.

Compound Pulleys

Compound pulleys consist of multiple fixed and movable pulleys combined. This type of pulley system provides a high mechanical advantage, making it suitable for lifting extremely heavy loads with minimal effort.

Choosing the Right Step Pulley

1. Load Requirement

Consider the maximum load the step pulley needs to handle. This will determine the size and strength requirements of the pulley and bearings, ensuring safe and efficient operation.

2. Speed Range

Determine the required speed range for your application. This will help in selecting the appropriate step pulley with the desired number of steps and diameter ratios to achieve the desired speed variations.

3. Space Limitations

Take into account any space limitations in your setup. Ensure that the selected step pulley fits within the available space without interfering with other components or causing clearance issues.

4. Belt Type and Size

Consider the type and size of the drive belt that will be used with the step pulley. Ensure compatibility between the pulley and belt, as well as proper tensioning for reliable power transmission.

5. Operating Conditions

Assess the operating conditions, such as temperature, humidity, and exposure to contaminants. Choose a step pulley with bearings that can withstand these conditions and maintain optimal performance over time.

About Us

HZPT specializes in the design, development, and manufacturing of high-performance step pulleys with bearings. We also offer procurement and export services for automotive aftermarket parts to meet all customer needs. Our products are well-received in the European, South American, and Australian markets, earning the trust of many customers. We prioritize product quality and uphold a “customer-first service” policy. With a young, dynamic, and capable team, we believe we can provide professional services to meet all your requirements. Fast delivery is one of our advantages. In China, we have a dedicated factory for new product development and OEM services. Additionally, we have a well-stocked warehouse and timely distribution to fulfill the needs of many customers. We continuously strive to improve our services and offer top-quality products at competitive prices. We appreciate any inquiries or feedback, so please feel free to contact us.

Our Product and Company Advantages

- High-Quality Materials: Our step pulleys with bearings are made from high-quality materials that ensure durability and reliability.

- Precision Engineering: We utilize advanced manufacturing techniques and precision engineering to produce step pulleys with accurate dimensions and smooth operation.

- Customization Options: We offer customization options to meet specific requirements, such as custom sizes, materials, and configurations.

- Expertise and Experience: Our team has extensive expertise and experience in the design and production of step pulleys, ensuring top-notch quality and performance.

- Excellent Customer Support: We provide excellent customer support, assisting customers throughout the entire process, from product selection to after-sales service.