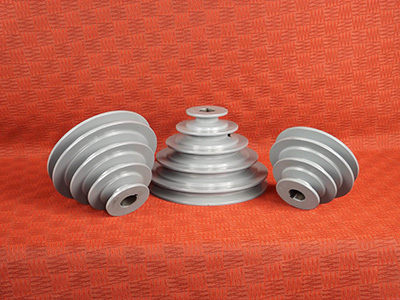

Step Pulley for Shipping

Introduction

In the world of shipping, step pulleys play a crucial role in the smooth operation of various machinery and equipment. These versatile devices are designed to provide different speed ratios by changing the diameter of the pulley. They are widely used in shipping industry due to their ability to control speed and transmit power efficiently.

Why do we use stepped pulley?

– Flexibility in Speed Control: Stepped pulleys allow for easy adjustment of speed ratios, enabling precise control over the speed of shipping machinery. This is essential for optimizing performance and efficiency in various shipping processes.

– Power Transmission Efficiency: With their unique design, stepped pulleys ensure efficient power transmission by maintaining constant belt tension and minimizing slippage. This results in reduced energy loss and increased overall efficiency in shipping operations.

– Smooth Load Handling: Stepped pulleys enable smooth load handling by providing gradual speed changes during the operation of shipping equipment. This helps to minimize shocks and vibrations, ensuring the safe transportation of goods.

– Enhanced Durability: Stepped pulleys are built to withstand heavy loads and harsh operating conditions commonly encountered in the shipping industry. Their robust construction and high-quality materials ensure long-lasting performance and reliability.

– Versatile Applications: Stepped pulleys find applications in various shipping equipment such as conveyor systems, cranes, winches, and elevators. Their adaptability makes them indispensable for efficient cargo handling and transportation.

What is a stepped cone pulley used for?

– Speed Control in Machine Tools: Stepped cone pulleys are commonly used in machine tools to provide multiple speed options for different machining operations. This allows operators to optimize cutting speeds and improve overall machining efficiency.

– Lathe Spindle Speed Adjustment: In lathe machines, stepped cone pulleys enable operators to change the spindle speed according to the material being machined and the desired surface finish. This ensures precise and efficient turning operations.

– Mechanical Variable Speed Drives: Stepped cone pulleys form an integral part of mechanical variable speed drives, which are widely used in shipping machinery. These drives allow for smooth and continuous speed adjustments, meeting the diverse requirements of shipping processes.

Types of Pulleys

There are three main types of pulleys used in shipping applications:

– Step Pulleys: As discussed earlier, step pulleys provide different speed ratios by changing the diameter of the pulley. They are commonly used for speed control in shipping equipment.

– V-Belt Pulleys: V-belt pulleys are designed to work with V-belts, which provide high friction and reliable power transmission. They are suitable for heavy-load applications in shipping machinery.

– Timing Belt Pulleys: Timing belt pulleys are used in synchronization systems, ensuring precise motion control in shipping equipment. They are commonly employed in conveyor systems and other automated shipping processes.

Choosing the Right Step Pulley

When selecting or customizing a step pulley for specific shipping requirements, consider the following parameters:

– Speed Range: Determine the desired range of speeds required for efficient shipping operations.

– Power Transmission Capacity: Consider the maximum load and power requirements of the machinery to ensure the step pulley can handle the intended workload.

– Material Selection: Choose a step pulley made from high-quality materials that can withstand the environmental conditions and demands of the shipping industry.

– Belt Type Compatibility: Ensure the step pulley is compatible with the type of belt being used in the shipping equipment for optimal power transmission.

– Ease of Maintenance: Select a step pulley that is easy to clean, lubricate, and maintain to minimize downtime and ensure longevity.

About HZPT

HZPT specializes in the design, development, and manufacturing of high-performance step pulleys for shipping applications. We also provide procurement and export services for aftermarket automotive parts to meet the needs of our customers worldwide. Our products are well-received in the European, South American, and Australian markets, earning the trust of many clients.

At HZPT, we prioritize product quality and adhere to a “customer-first service” policy. With a young, dynamic, and capable team, we believe that we can provide professional services to fulfill all your requirements. Our quick delivery is one of our advantages, ensuring prompt shipment to meet the demands of numerous customers.

In China, we have a dedicated factory for the development of new products and OEM services. Additionally, we maintain a well-stocked warehouse for efficient distribution to fulfill the needs of our customers. We continuously strive to improve our services and offer top-quality products at competitive prices.

We appreciate any inquiries or feedback and encourage you to contact us at any time. As a company specializing in the production and sales of step pulleys, we are confident in attracting customers to collaborate with us. Here are five key points highlighting our product and company advantages:

1. Extensive Product Range: We offer a wide variety of step pulleys suitable for different shipping applications, ensuring that you can find the perfect fit for your needs.

2. Superior Quality: Our step pulleys are manufactured with precision and using high-quality materials, guaranteeing durability and reliable performance.

3. Customization Options: We provide options for customizing step pulleys to meet specific requirements, ensuring the best possible performance in your shipping operations.

4. Technical Expertise: With our experienced team of engineers and technicians, we can offer expert advice and support to help you optimize the performance of your shipping equipment.

5. Excellent Customer Service: We pride ourselves on our customer-centric approach, providing timely assistance, efficient communication, and swift resolution of any concerns or queries.

Partner with HZPT for all your step pulley needs and experience the difference in performance and efficiency in your shipping operations.