Product Description

Customize Rubber & Plastic & PU products

— According to samples or drawings

For fast quotation, please confirm below details;

1. Product type

2. Size (provide samples or 2d/3d drawings for reference)

3. Specific material (or let us using environment)

4. Quantity request

5. Prefer color

Description

- OEM size suit for customers’ requirment

- Multiple color can be choosed

- Engraved or embossed logo accepted

- Large order quantity are able to be fulfilled

- Strict quality control system

- In time delivery and thoughtful custom-service

- Certification: SGS, GB/T 19001-2016, ISO9001:2005

| Product Specifications | |

| Service | Product & Mold Design and Making,Material Modification,Surface Treatment,Assembly,Custom Packaging |

| Technology | Injection molding, CNC machining, Extrusion, vacuum forming, Compression molding, Over molding&insert molding |

| Material | Rubber: NR, NBR, Neoprene, EPDM, Silicone, FKM, BR/SBR, PU, TPE, TPV, TPU,etc Plastic: PA6 PA66 PA6+GF PA66+GF, ABS, POM, PP, PE, LDPE, HDPE, UHMWPE, PTFE, PVC, PC, PEEK, PS, PET, PBT, TPU, TPE,etc |

| Color | any color according to Pantone code |

| Size | As per customer’s requirements |

| Additives | UV absorbers, Flame retardants, Plasticizers, Colorants, Carbon fibers, Glass fibers |

| Surface Treatment | Polishing finish, Glossy Finish, Texture Finish, silk printing, painting, As-machined |

| Biggest Part Size | 1500*1500*1000mm |

| Tolerance | 0.01mm–0.001mm |

| Product Volume | 50,000,000 Pcs/Month |

| Drawing Format | 2D Drawing: PDF/JPG/PNG 3D Drawing: STEP/STP/IGS/DXF/DWG |

| Packaging | Can be customized packaging |

| Shipping | We have long-term cooperation with international shipping agents and express companies so that shipping safety and arrival time are secured |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Mold Specifications | |

| Mold Life | 500k-5000k Shots |

| Mold Material | 136/2344/718/738/NAK80/P20, etc. |

| Mold Cavity | Single cavity, multi-cavity |

| Runner System | hot runner and cold runner |

| Mold Making Machine: | Vertical Machining center, plano-milling machine, EDM, WEDM, etc |

| other | 24 hours instant and comfortable customer service shipping status notification during delivery |

Our Factory

Zhongde is a leading manufacture of OEM parts in plastic &rubber parts. Our workers are experienced and professional in international trade.We are always pursuing providing better quality products and more competitive price in shorter period. With a experienced engineer team, production team and Professional sales team.we are confident to help you develop and manufacture your product.

Our Machine

We have different types of machines to meet different requriements. Most our machines were imported from overseal. The highest rotate speed of CNC machining center can reach to 20,000RPM. The largest vulcanize rubber machine can produce rubber parts within 3000mm.

Our Certification

Zhongde is a SGS verified manufacture. We have passed ISO9001:2005 quality control certifacation as well as environment management certification.

Contact Us

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Certification: | CE, ISO |

|---|---|

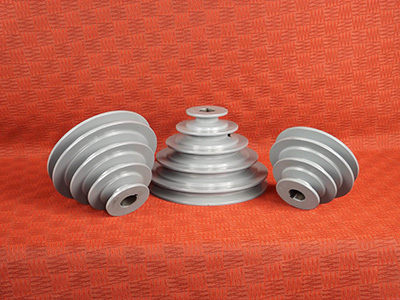

| Pulley Sizes: | Type O |

| Manufacturing Process: | Casting |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

How do step pulleys contribute to the functionality of drill presses and lathes?

Step pulleys play a crucial role in enhancing the functionality of drill presses and lathes. Here’s how they contribute:

1. Variable Speed Control:

Step pulleys enable variable speed control in drill presses and lathes, allowing users to adjust the rotational speed of the spindle or workpiece. By changing the position of the drive belt on different steps of the pulley, operators can select different speed settings to match the requirements of various materials, cutting tools, or machining operations. This versatility in speed control enhances the precision and flexibility of these machines.

2. Wide Speed Range:

Step pulleys provide a wide range of speed options in drill presses and lathes. The pulley system typically consists of multiple steps with different diameters, each corresponding to a specific speed ratio. This allows users to choose the desired speed within the available range, accommodating a variety of cutting or drilling tasks, from high-speed operations to slow and precise operations.

3. Easy Speed Changes:

Changing the speed on a drill press or lathe equipped with step pulleys is relatively straightforward. By manually adjusting the position of the drive belt on the pulley steps or by engaging different pulley combinations (in machines with multiple pulleys), operators can quickly switch between speed settings. This ease of speed changes enables efficient workflow and facilitates adaptability to different machining requirements.

4. Cost-Effective Solution:

Step pulleys provide a cost-effective speed control mechanism for drill presses and lathes. Compared to more complex electronic speed control systems or variable frequency drives, step pulleys are relatively simple and affordable. They offer a reliable and efficient means of achieving variable speed functionality without the need for sophisticated electronic components or significant additional costs.

5. Reliable and Durable:

Step pulleys are known for their reliability and durability, making them suitable for the demanding operations of drill presses and lathes. They are designed to withstand high rotational speeds and heavy loads, ensuring consistent performance over extended periods of use. With proper maintenance and lubrication, step pulleys can provide long-lasting service in these machining applications.

6. Compatibility with Belts or Cables:

Step pulleys are compatible with various types of belts or cables, allowing for flexibility in the selection of power transmission components. Drill presses and lathes can be equipped with V-belts, flat belts, or even cables, depending on the specific requirements of the machine and the desired power transmission characteristics. This compatibility enhances the versatility and adaptability of the pulley system.

Overall, step pulleys significantly enhance the functionality of drill presses and lathes by providing variable speed control, a wide speed range, easy speed changes, cost-effective solutions, reliability, and compatibility with different power transmission components. These features empower operators to perform a broad range of machining tasks with precision and efficiency.

What are some real-world examples of step pulley applications in various industries?

Step pulleys find numerous applications across various industries. Here are some real-world examples of step pulley applications:

1. Machinery and Manufacturing:

– Drill Presses: Step pulleys are commonly used in drill presses to provide variable speed control for drilling operations. Different pulley positions allow operators to select the appropriate speed for drilling various materials.

– Lathes: Step pulleys play a crucial role in lathes by enabling variable speed control for turning operations. They allow operators to adjust the rotational speed of the workpiece to achieve desired cuts and surface finishes.

– Milling Machines: Step pulleys are utilized in milling machines to control the speed of the cutting tool. By changing the position of the belt on the pulleys, operators can achieve different cutting speeds for various materials and milling operations.

2. Automotive Industry:

– Automotive Transmissions: Step pulleys, particularly variable speed pulleys, are used in some automotive transmissions to provide seamless and efficient speed control. They allow for smooth acceleration and optimal power distribution.

– Engine Accessories: Step pulleys are employed in various engine accessories such as water pumps, alternators, and superchargers. They enable these components to operate at different speeds, optimizing their performance and power consumption.

3. Exercise Equipment:

– Treadmills: Step pulleys with variable speed functionality are used in treadmills to offer adjustable running speeds. Users can select different speed settings based on their fitness levels and workout goals.

– Stationary Bikes: Step pulleys are utilized in stationary bikes to allow users to adjust the resistance and simulate different biking terrains. By changing the belt position on the pulleys, users can vary the pedaling effort required.

4. Industrial Machinery:

– Conveyor Systems: Step pulleys are employed in conveyor systems to control the speed at which materials or products move along the conveyor belt. Different pulley positions enable speed adjustments to match production requirements.

– Packaging Machines: Step pulleys are used in packaging machines to regulate the speed of the packaging process. They ensure precise and synchronized movements of various components, such as feeding systems, sealing mechanisms, and labeling devices.

5. Printing Industry:

– Printing Presses: Step pulleys are utilized in printing presses to control the speed of the printing cylinders or rollers. They enable precise control over the ink transfer and paper feeding processes, ensuring accurate and high-quality printing results.

6. Agricultural Equipment:

– Harvesters: Step pulleys are employed in combine harvesters to adjust the rotational speed of cutting heads and threshing mechanisms. This allows for efficient crop harvesting and processing.

– Irrigation Systems: Step pulleys are used in irrigation systems to control the speed of pumps or water distribution mechanisms. They allow for precise control over water flow rates and irrigation patterns.

These are just a few examples of step pulley applications in various industries. The versatility and adaptability of step pulleys make them valuable components in a wide range of machinery and equipment, enabling efficient speed control and enhancing overall performance.

How does a step pulley assist in changing the speed and power transmission?

A step pulley plays a crucial role in changing the speed and power transmission in mechanical systems. Here’s how it assists in these aspects:

1. Speed Variation:

A step pulley provides different speed options by changing the effective diameter of the pulley. The pulley wheel has multiple steps or levels of varying diameters. By moving the belt or chain from one step to another, the speed ratio between the driving pulley and the driven pulley is altered. This allows for speed variation in the power transmission system.

2. Speed Adjustment:

Each step on the step pulley corresponds to a specific diameter, and therefore, a specific speed ratio. By selecting different steps, the rotational speed of the driven component can be adjusted. This is particularly useful when different operating speeds are required for different tasks or when the load on the system changes.

3. Power Transmission:

A step pulley facilitates power transmission by transferring rotational energy from the driving pulley to the driven pulley. The belt or chain engaged with the steps of the pulley transfers torque from the driving source to the driven component. The power transmitted depends on the speed ratio and the torque applied at the driving pulley.

4. Mechanical Advantage:

Depending on the selected step and corresponding diameter, a step pulley can provide a mechanical advantage. By choosing a smaller diameter step, the pulley effectively increases the torque while reducing the rotational speed. This can be advantageous in systems where high torque is required, such as in milling machines or lathes.

5. Adjustability:

The manual adjustability of a step pulley allows operators to change the speed and power transmission characteristics according to specific requirements. By manually shifting the belt or chain to different steps, the speed and torque output can be adjusted without the need for complex transmission systems or additional components.

Overall, a step pulley provides a simple and effective means of changing speed and power transmission in mechanical systems, making it a versatile component in various applications.

editor by CX

2023-09-28