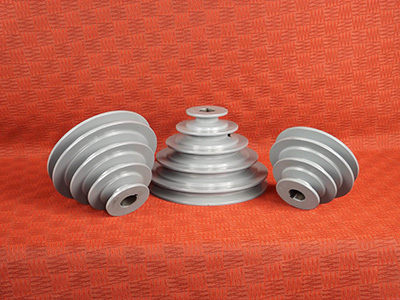

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type D |

| Manufacturing Process: | Forging |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What maintenance procedures are necessary to ensure the reliability of step pulleys?

To ensure the reliability of step pulleys, certain maintenance procedures should be followed. Here are some essential maintenance procedures:

1. Regular Inspection:

Perform regular visual inspections of the step pulleys to check for any signs of wear, damage, or misalignment. Look for cracks, chips, or excessive wear on the pulley steps. Ensure that the pulley is properly aligned with the belt or cable and that there is no excessive play or wobbling.

2. Lubrication:

Proper lubrication is crucial for the smooth operation of step pulleys. Follow the manufacturer’s guidelines on lubrication frequency and use the recommended lubricant. Apply lubricant to the pulley shaft and bearings to reduce friction and prevent premature wear.

3. Belt or Cable Maintenance:

Inspect the belts or cables regularly for signs of wear, cracking, or stretching. Replace any worn-out or damaged belts or cables promptly. Ensure that the belts or cables are correctly tensioned and properly aligned with the step pulleys to prevent slippage and optimize power transmission.

4. Cleaning:

Keep the step pulleys clean and free from debris, dust, or other contaminants. Regularly clean the pulleys using a soft brush or cloth to remove any buildup that may affect their performance. Avoid using harsh chemicals that could damage the pulley surface or belt material.

5. Belt Alignment:

Check the alignment of the belts or cables on the step pulleys. Misaligned belts can cause uneven wear, increased friction, and reduced efficiency. Adjust the pulley position or tension as necessary to ensure proper alignment.

6. Preventive Maintenance:

Implement a preventive maintenance schedule for the machinery that includes step pulleys. Schedule periodic maintenance tasks, such as pulley inspections, lubrication, and belt or cable replacements, to prevent unexpected failures and ensure the long-term reliability of the pulleys.

7. Professional Expertise:

For complex machinery or critical applications, it is advisable to seek the expertise of qualified technicians or maintenance professionals. They can provide specialized knowledge and perform more in-depth maintenance procedures to ensure the reliability and optimal performance of the step pulleys.

By following these maintenance procedures, step pulleys can be kept in good condition, minimizing the risk of failures, optimizing performance, and extending their service life.

What safety considerations should be kept in mind when working with step pulleys?

Working with step pulleys involves certain safety considerations to prevent accidents and ensure the well-being of individuals involved. Here are some important safety guidelines to keep in mind:

1. Read and Follow Manufacturer’s Instructions:

Before operating any machinery or equipment with step pulleys, carefully read and understand the manufacturer’s instructions, warnings, and safety guidelines. Follow them strictly to ensure safe usage.

2. Wear Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection, when working with step pulleys. PPE helps protect against potential hazards, including flying debris, entanglement, and noise.

3. Machine Guarding:

Ensure that all necessary machine guards and safety shields are in place and properly functioning. Machine guards help prevent accidental contact with moving parts, including step pulleys, reducing the risk of injury.

4. Lockout/Tagout Procedures:

Follow lockout/tagout procedures when performing maintenance or repair tasks on machinery with step pulleys. Lockout/tagout involves isolating the equipment from its power source and securing it to prevent accidental startup during maintenance activities.

5. Proper Training and Supervision:

Ensure that operators and maintenance personnel receive proper training on the safe operation and maintenance of machinery with step pulleys. Supervise their work initially until they have gained sufficient experience and competence.

6. Avoid Loose Clothing and Jewelry:

Avoid wearing loose clothing, jewelry, or anything that could get entangled in the moving parts of the machinery, including step pulleys. Loose items can pose a serious risk of entanglement and injury.

7. Use Proper Tools and Equipment:

Use the appropriate tools and equipment when working with step pulleys. Using improper tools or makeshift solutions can lead to accidents or damage to the equipment.

8. Regular Maintenance and Inspection:

Perform regular maintenance and inspection of the machinery and step pulley system. Check for any signs of wear, damage, or misalignment. Address any issues promptly to ensure safe and efficient operation.

9. Report and Address Safety Concerns:

If you notice any safety concerns or potential hazards related to the step pulley system, promptly report them to the appropriate personnel. Take necessary actions to address the concerns and ensure a safe working environment.

10. Follow Safe Work Practices:

Adhere to safe work practices, such as keeping the work area clean and organized, maintaining proper lighting, and avoiding distractions. These practices contribute to a safer work environment when working with step pulleys.

By following these safety considerations and guidelines, you can minimize the risks associated with working with step pulleys and create a safer working environment for yourself and others.

How does a step pulley assist in changing the speed and power transmission?

A step pulley plays a crucial role in changing the speed and power transmission in mechanical systems. Here’s how it assists in these aspects:

1. Speed Variation:

A step pulley provides different speed options by changing the effective diameter of the pulley. The pulley wheel has multiple steps or levels of varying diameters. By moving the belt or chain from one step to another, the speed ratio between the driving pulley and the driven pulley is altered. This allows for speed variation in the power transmission system.

2. Speed Adjustment:

Each step on the step pulley corresponds to a specific diameter, and therefore, a specific speed ratio. By selecting different steps, the rotational speed of the driven component can be adjusted. This is particularly useful when different operating speeds are required for different tasks or when the load on the system changes.

3. Power Transmission:

A step pulley facilitates power transmission by transferring rotational energy from the driving pulley to the driven pulley. The belt or chain engaged with the steps of the pulley transfers torque from the driving source to the driven component. The power transmitted depends on the speed ratio and the torque applied at the driving pulley.

4. Mechanical Advantage:

Depending on the selected step and corresponding diameter, a step pulley can provide a mechanical advantage. By choosing a smaller diameter step, the pulley effectively increases the torque while reducing the rotational speed. This can be advantageous in systems where high torque is required, such as in milling machines or lathes.

5. Adjustability:

The manual adjustability of a step pulley allows operators to change the speed and power transmission characteristics according to specific requirements. By manually shifting the belt or chain to different steps, the speed and torque output can be adjusted without the need for complex transmission systems or additional components.

Overall, a step pulley provides a simple and effective means of changing speed and power transmission in mechanical systems, making it a versatile component in various applications.

editor by CX

2023-11-14