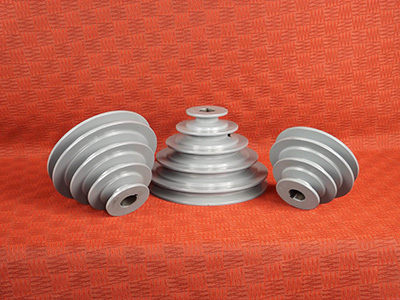

Product Description

Product Description

| Material | Aluminium Alloy,Carbon Steel,Stainless steel,Copper,Brass,Nylon,Plastic(Customized Material) |

| Producing Equipment | 3 Axis,4 Axis,5 Axis CNC Machines,Automatic Lathe Machines,Stamping Machines,CNC Milling machines,CNC Turning Machines,Turning Milling Compound Machines,Grinding Machines,Rolling Machines,Laser Machines. |

| Surface Treatment | Anodizing,Polishing,Electroplating,Heat Treatment,Spray Paint,Sand Blasting. |

| Testing Equipment | Salt Spray Test, Hardness Tester, Coating Thickness Tester, Two Dimensions Measuring Instrument. |

| Quality Testing | 100% Quality Inspection Before Shipment. |

| Lead Time | Generally, The Delivery Date Is 7-15 Days,Delivery Time of Bulk Order Is More Than 15 days. |

| Tolerance and Roughness | Size Tolerance:+/-0.005 – 0.01mm,Roughness: Ra0.2 – Ra3.2 (Custom Size Requirements) |

| Cargo Shipment | Express(DHL,Fedex,UPS, TNT ),Air shipment+Local Express Delivery,Ocean Shipment. |

| Main Markets | America, Europe, Australia, Asia. |

| Payment Type | T/T, L/C, Paypal,Western Union,Others. |

Packaging & Shipping

Company Profile

HangZhou Fuyouda Technology Co., Ltd. Was established in city known as the “world factory”-HangZhou. We are factory and have many kinds of machine, such as 5-axis CNC machines, lath machines, turning milling compound machines. After 10 years of R&D, production and sales, we have 80% market share in the field of 3D printer parts in China and we are specializing in CNC machinig for 10 years. We are committed to creating a work and production environment that is above the industry average. We adopt scientific production management methods to improve production efficiency and reduce production costs. Please believe and choose us! We adhere to the management principles of “Quality First, Customer first and Credit-based” since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a CHINAMFG situation since the trend of economic globalization has developed with anirresistible force.

Our Advantages

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Color: | Customized |

| Customized: | Customized |

| Standard: | International |

| Type: | Connection |

| Material: | Aluminum |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What maintenance procedures are necessary to ensure the reliability of step pulleys?

To ensure the reliability of step pulleys, certain maintenance procedures should be followed. Here are some essential maintenance procedures:

1. Regular Inspection:

Perform regular visual inspections of the step pulleys to check for any signs of wear, damage, or misalignment. Look for cracks, chips, or excessive wear on the pulley steps. Ensure that the pulley is properly aligned with the belt or cable and that there is no excessive play or wobbling.

2. Lubrication:

Proper lubrication is crucial for the smooth operation of step pulleys. Follow the manufacturer’s guidelines on lubrication frequency and use the recommended lubricant. Apply lubricant to the pulley shaft and bearings to reduce friction and prevent premature wear.

3. Belt or Cable Maintenance:

Inspect the belts or cables regularly for signs of wear, cracking, or stretching. Replace any worn-out or damaged belts or cables promptly. Ensure that the belts or cables are correctly tensioned and properly aligned with the step pulleys to prevent slippage and optimize power transmission.

4. Cleaning:

Keep the step pulleys clean and free from debris, dust, or other contaminants. Regularly clean the pulleys using a soft brush or cloth to remove any buildup that may affect their performance. Avoid using harsh chemicals that could damage the pulley surface or belt material.

5. Belt Alignment:

Check the alignment of the belts or cables on the step pulleys. Misaligned belts can cause uneven wear, increased friction, and reduced efficiency. Adjust the pulley position or tension as necessary to ensure proper alignment.

6. Preventive Maintenance:

Implement a preventive maintenance schedule for the machinery that includes step pulleys. Schedule periodic maintenance tasks, such as pulley inspections, lubrication, and belt or cable replacements, to prevent unexpected failures and ensure the long-term reliability of the pulleys.

7. Professional Expertise:

For complex machinery or critical applications, it is advisable to seek the expertise of qualified technicians or maintenance professionals. They can provide specialized knowledge and perform more in-depth maintenance procedures to ensure the reliability and optimal performance of the step pulleys.

By following these maintenance procedures, step pulleys can be kept in good condition, minimizing the risk of failures, optimizing performance, and extending their service life.

What are some real-world examples of step pulley applications in various industries?

Step pulleys find numerous applications across various industries. Here are some real-world examples of step pulley applications:

1. Machinery and Manufacturing:

– Drill Presses: Step pulleys are commonly used in drill presses to provide variable speed control for drilling operations. Different pulley positions allow operators to select the appropriate speed for drilling various materials.

– Lathes: Step pulleys play a crucial role in lathes by enabling variable speed control for turning operations. They allow operators to adjust the rotational speed of the workpiece to achieve desired cuts and surface finishes.

– Milling Machines: Step pulleys are utilized in milling machines to control the speed of the cutting tool. By changing the position of the belt on the pulleys, operators can achieve different cutting speeds for various materials and milling operations.

2. Automotive Industry:

– Automotive Transmissions: Step pulleys, particularly variable speed pulleys, are used in some automotive transmissions to provide seamless and efficient speed control. They allow for smooth acceleration and optimal power distribution.

– Engine Accessories: Step pulleys are employed in various engine accessories such as water pumps, alternators, and superchargers. They enable these components to operate at different speeds, optimizing their performance and power consumption.

3. Exercise Equipment:

– Treadmills: Step pulleys with variable speed functionality are used in treadmills to offer adjustable running speeds. Users can select different speed settings based on their fitness levels and workout goals.

– Stationary Bikes: Step pulleys are utilized in stationary bikes to allow users to adjust the resistance and simulate different biking terrains. By changing the belt position on the pulleys, users can vary the pedaling effort required.

4. Industrial Machinery:

– Conveyor Systems: Step pulleys are employed in conveyor systems to control the speed at which materials or products move along the conveyor belt. Different pulley positions enable speed adjustments to match production requirements.

– Packaging Machines: Step pulleys are used in packaging machines to regulate the speed of the packaging process. They ensure precise and synchronized movements of various components, such as feeding systems, sealing mechanisms, and labeling devices.

5. Printing Industry:

– Printing Presses: Step pulleys are utilized in printing presses to control the speed of the printing cylinders or rollers. They enable precise control over the ink transfer and paper feeding processes, ensuring accurate and high-quality printing results.

6. Agricultural Equipment:

– Harvesters: Step pulleys are employed in combine harvesters to adjust the rotational speed of cutting heads and threshing mechanisms. This allows for efficient crop harvesting and processing.

– Irrigation Systems: Step pulleys are used in irrigation systems to control the speed of pumps or water distribution mechanisms. They allow for precise control over water flow rates and irrigation patterns.

These are just a few examples of step pulley applications in various industries. The versatility and adaptability of step pulleys make them valuable components in a wide range of machinery and equipment, enabling efficient speed control and enhancing overall performance.

In which industries and applications are step pulleys commonly used?

Step pulleys find widespread use in various industries and applications where adjustable speed control is required. Here are some industries and applications where step pulleys are commonly used:

1. Machine Tools:

Step pulleys are extensively used in machine tools such as drill presses, milling machines, and lathes. They allow operators to adjust the rotational speed of cutting tools, enabling precise machining operations.

2. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems often utilize step pulleys in blower motors and fans. These pulleys enable adjusting the speed of the fan to control airflow and temperature regulation.

3. Automotive Industry:

Step pulleys are employed in various automotive applications. They can be found in engine accessories like alternators and power steering systems, where they allow for adjustable speed control.

4. Industrial Machinery:

Step pulleys are used in a wide range of industrial machinery, including conveyors, packaging machines, textile machines, and printing presses. They provide speed variation for different production requirements.

5. Exercise Equipment:

Step pulleys are utilized in exercise equipment like treadmills, stationary bikes, and elliptical machines. They allow users to adjust the difficulty level and intensity of their workouts by changing the speed or resistance.

6. Garage Door Openers:

Step pulleys are commonly found in garage door openers. They enable smooth and controlled opening and closing of garage doors by adjusting the speed and torque applied to the door mechanism.

7. Textile Industry:

In textile manufacturing, step pulleys are used in textile machines such as spinning frames and weaving looms. They provide speed control for various stages of the textile production process.

8. Woodworking Machinery:

Step pulleys are utilized in woodworking machinery, including table saws, band saws, and sanding machines. They enable operators to adjust the speed of cutting or sanding tools for different types of wood and desired finishes.

These are just a few examples, and step pulleys can be found in numerous other industries and applications where adjustable speed control is essential.

editor by CX

2024-03-09