Product Description

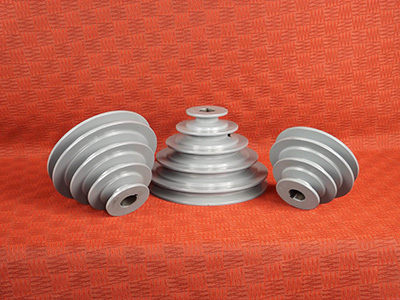

V Belt Step Pulley Sheave Steel Iron Metal Groove Transmission Machine Parts Timing Manufacture Best Sale Cutter Metal Durable European Standard Durable Pulleys

Product Description

Pulleys belonging to wheel hub components are generally large in size, and their manufacturing processes are mainly casting and forging. Generally, the design with large size is cast iron (good casting performance), and cast steel is rarely used (poor casting performance); Generally, the smaller size can be designed as forgings and the material is steel. Belt pulley is mainly used for long-distance power transmission, such as the output of small diesel engines, agricultural vehicles, tractors, automobiles, mining machinery, mechanical processing equipment, textile machinery, packaging machinery, lathes, forging machines, power transmission of some small horsepower motorcycles, power transmission of agricultural machinery, air compressors, reducers, reducers, generators, cotton ginners, etc.

V-Belt Pulley:

The specifications of V-belts are divided by the dimensions of back width (top width) and height (thickness). According to different dimensions of back width (top width) and height (thickness), V-belts of different standards have different models. The pitch width, top width and height of V-belts of each model are different, so the pulley must also make various groove types according to the shape of V-belts; These different groove types determine various types of pulley.

| American Standard | |

AK/AKH BK/BKH TA/TB/TC Series Sheaves |

B/C/D Series Sheaves |

Poly-V Sheaves |

Variable Speed Sheaves |

| 3V/5V/8V sheaves | Bushings Split Taper Bushings/QD Bushings/TB Bushings |

European standard (SPA CHINAMFG SPC SPZ) |

|

Belt Pulleys for Taper Bushings |

V belt pulley with CHINAMFG hub |

Adjustable Speed V Belt Pulleys |

Flat Belt Pulleys For Taper Bushes |

If You Purchase An Alternator Just About Anywhere, It Will Not Include This Dual V-Belt Pulley Will Not Be Available & Your Must Transfer It From Your Old Alternator.However, If You Need This Pulley And Your Repair Shop Exchanged Your Alternator For A Core & Forgot To Swap It Out, This Is The Cure For Your Problem.This Dual Pulley Is Hard To Come By & Many Years Back & This One Is A Direct Fit For The Full Size Jeeps.This Dual V-Belt Pulley Has A Nice Chrome Finish & Is Made Of Higher Quality Materials For Strength & Durability.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do step pulleys contribute to the functionality of drill presses and lathes?

Step pulleys play a crucial role in enhancing the functionality of drill presses and lathes. Here’s how they contribute:

1. Variable Speed Control:

Step pulleys enable variable speed control in drill presses and lathes, allowing users to adjust the rotational speed of the spindle or workpiece. By changing the position of the drive belt on different steps of the pulley, operators can select different speed settings to match the requirements of various materials, cutting tools, or machining operations. This versatility in speed control enhances the precision and flexibility of these machines.

2. Wide Speed Range:

Step pulleys provide a wide range of speed options in drill presses and lathes. The pulley system typically consists of multiple steps with different diameters, each corresponding to a specific speed ratio. This allows users to choose the desired speed within the available range, accommodating a variety of cutting or drilling tasks, from high-speed operations to slow and precise operations.

3. Easy Speed Changes:

Changing the speed on a drill press or lathe equipped with step pulleys is relatively straightforward. By manually adjusting the position of the drive belt on the pulley steps or by engaging different pulley combinations (in machines with multiple pulleys), operators can quickly switch between speed settings. This ease of speed changes enables efficient workflow and facilitates adaptability to different machining requirements.

4. Cost-Effective Solution:

Step pulleys provide a cost-effective speed control mechanism for drill presses and lathes. Compared to more complex electronic speed control systems or variable frequency drives, step pulleys are relatively simple and affordable. They offer a reliable and efficient means of achieving variable speed functionality without the need for sophisticated electronic components or significant additional costs.

5. Reliable and Durable:

Step pulleys are known for their reliability and durability, making them suitable for the demanding operations of drill presses and lathes. They are designed to withstand high rotational speeds and heavy loads, ensuring consistent performance over extended periods of use. With proper maintenance and lubrication, step pulleys can provide long-lasting service in these machining applications.

6. Compatibility with Belts or Cables:

Step pulleys are compatible with various types of belts or cables, allowing for flexibility in the selection of power transmission components. Drill presses and lathes can be equipped with V-belts, flat belts, or even cables, depending on the specific requirements of the machine and the desired power transmission characteristics. This compatibility enhances the versatility and adaptability of the pulley system.

Overall, step pulleys significantly enhance the functionality of drill presses and lathes by providing variable speed control, a wide speed range, easy speed changes, cost-effective solutions, reliability, and compatibility with different power transmission components. These features empower operators to perform a broad range of machining tasks with precision and efficiency.

Are there different types of step pulleys, and how do they vary in applications?

Yes, there are different types of step pulleys, and they vary in applications based on their design and features. Here are some common types of step pulleys and their respective applications:

1. Single-Step Pulleys:

Single-step pulleys have a single groove and are typically used in applications where a simple speed reduction or power transmission is required. They are commonly found in small machinery or equipment, such as benchtop tools, where only one fixed speed is needed.

2. Multi-Step Pulleys:

Multi-step pulleys have multiple grooves of varying diameters. They offer several speed options by positioning the belt on different steps of the pulley. These pulleys are widely used in drill presses, lathes, milling machines, and other machinery that require variable speed control. The ability to change the belt position allows for different speed settings to match specific machining operations or material characteristics.

3. Cone Pulleys:

Cone pulleys have a tapered shape, resembling a cone. They offer a continuous range of speed options by adjusting the position along the taper. Cone pulleys are commonly used in lathes, where the tailstock can be moved to change the position of the drive belt on the cone pulley, resulting in a variable speed control. They provide smooth speed transitions and are suitable for applications that require fine adjustments in speed.

4. Variable Speed Pulleys:

Variable speed pulleys, also known as stepless or infinitely variable pulleys, offer a continuous range of speed control without discrete steps. They consist of two pulleys connected by a belt or chain, with one pulley changing its diameter to vary the speed. These pulleys are commonly used in applications where precise speed adjustments are required, such as automotive engines, industrial machinery, and exercise equipment.

5. Timing Pulleys:

Timing pulleys have teeth or grooves that mate with corresponding teeth on a timing belt. They are used in applications where precise synchronization between the pulley and the driven component is necessary. Timing pulleys are commonly found in robotics, 3D printers, CNC machines, and other precision systems.

6. Step Pulley Systems with Backgear:

Some step pulley systems incorporate a backgear mechanism. Backgear allows for additional speed reduction, enabling the machine to operate at even lower speeds. These systems are commonly found in heavy-duty industrial machinery, such as large lathes or milling machines, where high torque and low-speed operations are required.

The selection of a specific type of step pulley depends on the desired speed range, the level of speed control needed, the nature of the application, and the specific machinery or equipment requirements. It is essential to choose the appropriate type of step pulley to ensure optimal performance and efficiency in the intended application.

How does a step pulley assist in changing the speed and power transmission?

A step pulley plays a crucial role in changing the speed and power transmission in mechanical systems. Here’s how it assists in these aspects:

1. Speed Variation:

A step pulley provides different speed options by changing the effective diameter of the pulley. The pulley wheel has multiple steps or levels of varying diameters. By moving the belt or chain from one step to another, the speed ratio between the driving pulley and the driven pulley is altered. This allows for speed variation in the power transmission system.

2. Speed Adjustment:

Each step on the step pulley corresponds to a specific diameter, and therefore, a specific speed ratio. By selecting different steps, the rotational speed of the driven component can be adjusted. This is particularly useful when different operating speeds are required for different tasks or when the load on the system changes.

3. Power Transmission:

A step pulley facilitates power transmission by transferring rotational energy from the driving pulley to the driven pulley. The belt or chain engaged with the steps of the pulley transfers torque from the driving source to the driven component. The power transmitted depends on the speed ratio and the torque applied at the driving pulley.

4. Mechanical Advantage:

Depending on the selected step and corresponding diameter, a step pulley can provide a mechanical advantage. By choosing a smaller diameter step, the pulley effectively increases the torque while reducing the rotational speed. This can be advantageous in systems where high torque is required, such as in milling machines or lathes.

5. Adjustability:

The manual adjustability of a step pulley allows operators to change the speed and power transmission characteristics according to specific requirements. By manually shifting the belt or chain to different steps, the speed and torque output can be adjusted without the need for complex transmission systems or additional components.

Overall, a step pulley provides a simple and effective means of changing speed and power transmission in mechanical systems, making it a versatile component in various applications.

editor by CX

2024-05-10